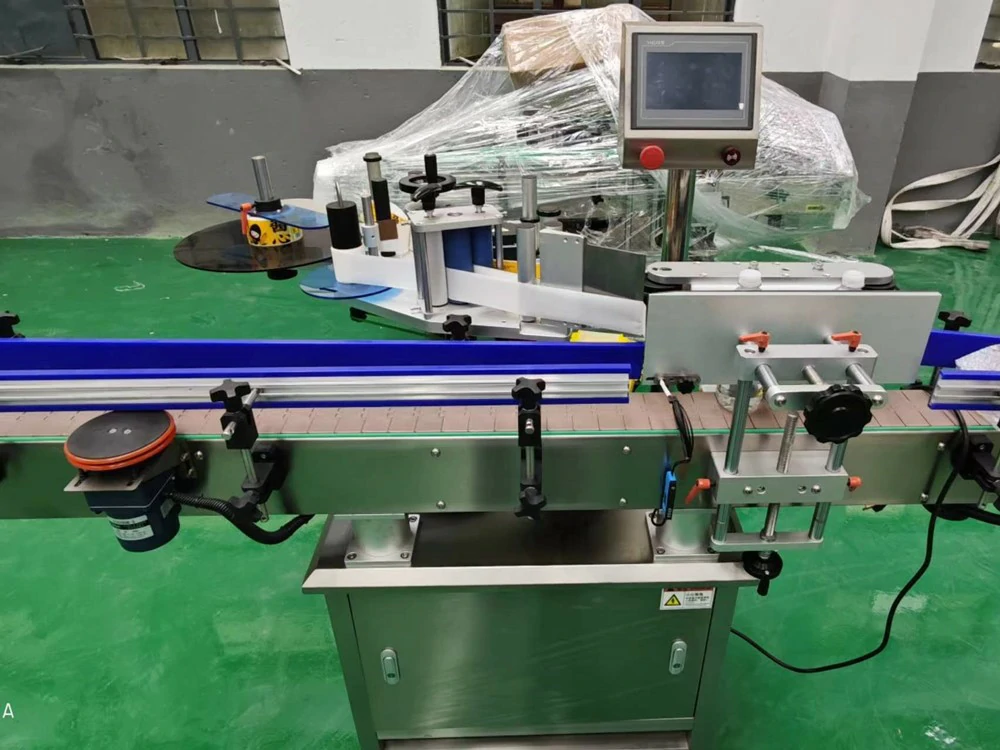

Automatic Linear Type Adhesive Sticker Labeling Machine

- Category:Labeling Machine

This machine is suitable for pasting continuous labels. It adopts local gluing method, with small glue consumption and low operating cost. The production capacity can reach 36,000 bottles/hour.

- Inquiry Email

Product features:

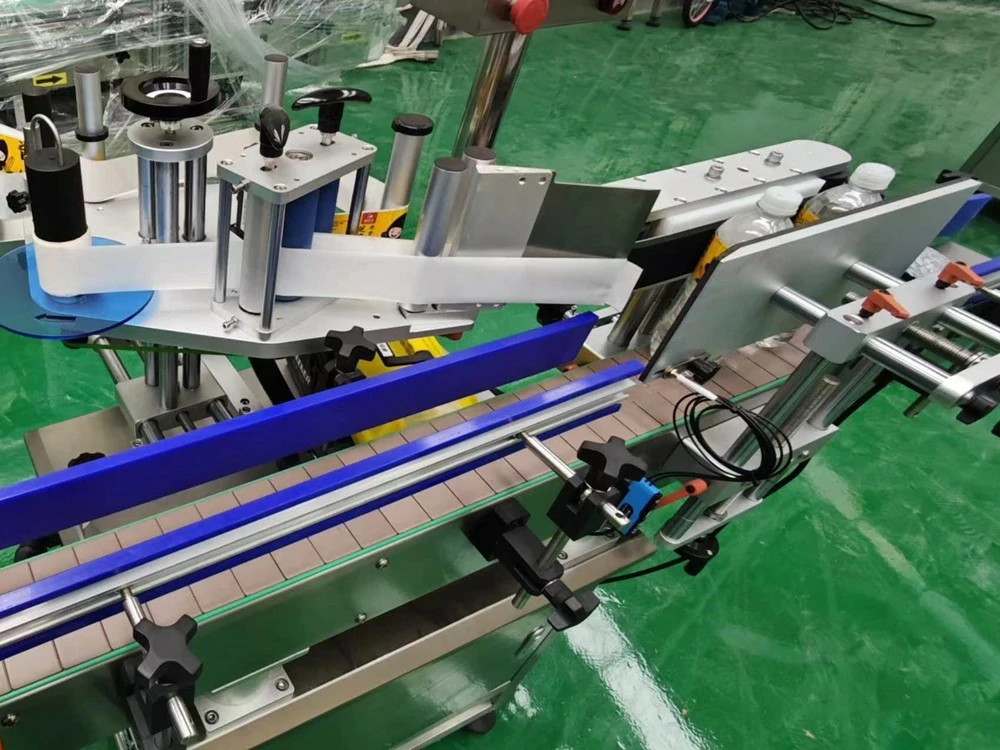

1. Double-sided rigid plastic synchronous guide chains are used to ensure the neutrality of the bottle, and the requirements for workers to place bottles and connect the bottles to the assembly line are low, which greatly reduces the difficulty of workers' operations or assembly line docking. It can be produced by a single machine or connected to an assembly line;

2. Equipped with a spring-loaded top-pressing mechanism to ensure smooth product transportation and effectively eliminate the inherent error of the bottle height;

3. Equipped with an automatic bottle separation mechanism, which automatically separates the spacing before guiding the bottle to ensure the stability of subsequent bottle guiding, transportation and labeling;

4. Equipped with a double-layer labeling mechanism, the first one ensures the labeling accuracy, and the second one is extrusion-type labeling, which effectively eliminates bubbles and ensures that the head and tail of the label are tightly attached;

5. Intelligent control, automatic photoelectric tracking, with no object without labeling, no label automatic correction and label automatic detection functions, to avoid waste of labels and missed labels;

6. The main materials of the equipment are stainless steel and aluminum alloy, which conforms to GMP production specifications, with a solid overall structure and beautiful appearance.

INQUIRY

CATEGORIES

CONTACT US

Name: General Manager

Mobile:+86 188 6222 6180

Whatsapp:+86 188 6222 6180

Email:libby@chinakbm.com

Add:No.3 Jinxiu Road, Jiangsu Yangtze International Metallurgical Industrial Park, Jinfeng Town, Zhangjiagang, Jiangsu, China